PROTOTYPE ELECTRIC CAR

Designer: PMRC - Personal Mobility Research Center Hongik University

Courtesy of Digital Hands – HDC Korea

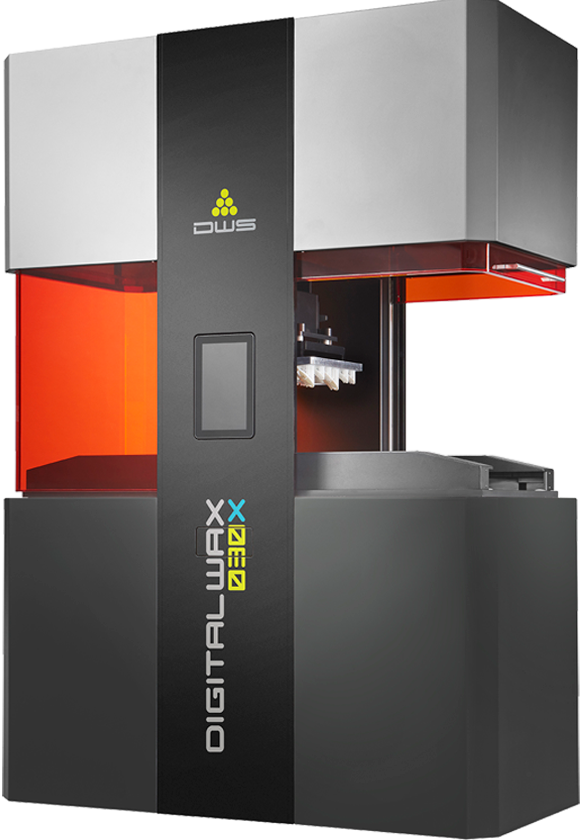

Researchers at Hongik University (Seoul, South Korea) designed this frame for an innovative electric car. The landmark Korean university chose DWS 3D printing to make its prototypes for testing the shape and design of the product. The electric car model was created using the DW 030X 3D printer with Invicta DL380 material.

It took 90 hours to produce the whole model, including the seat with its intricate lattice pattern.

Measuring 45 x 30 x 30 cm, the model was printed as assorted components, which were assembled afterwards.

This prototype of the car’s structure required smooth, finely detailed surfaces, while the seat, with its complex lattice texture, required minimal thickness, accuracy, and extreme precision. These requirements are fulfilled by our Invicta DL380 material.

Following minimal post-production processing (two-minute wash in water-alcohol solution and five minutes in the UV curing unit), the supports were removed, and the break points lightly sanded and polished with Vaseline.