LARGE FORMAT INDUSTRIAL 3D PRINTERS

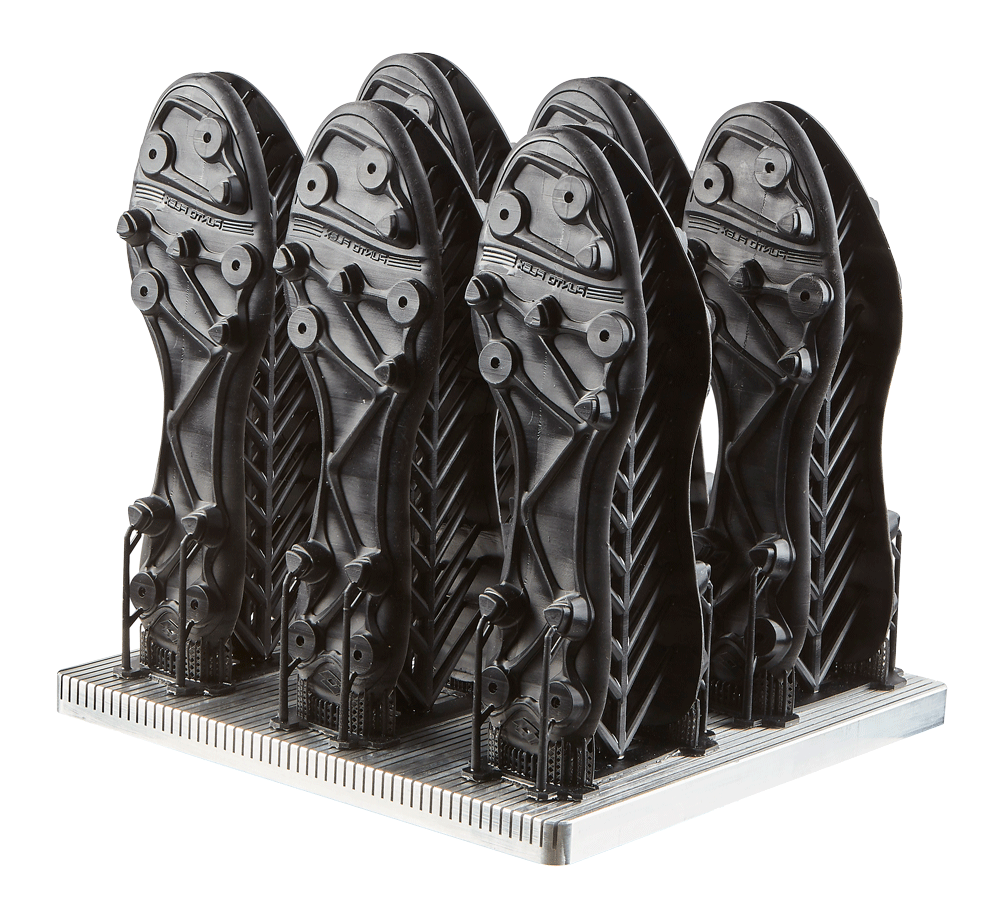

DWS professional 3D printers for the Manufacturing department, are characterised by high production volumes of functional parts.

The 3D printers of large dimensions, such as XPROQL, has a printing area of up to 50 cm in the Z axis.

DWS 3D printers use stereolithographic additive manufacturing (SLA) technology to produce parts of the highest precision and dimensional accuracy.

Born for rapid prototyping, they now play an important role in all stages of the industrial process, from the production of maquettes used for the executive design verification and the production of the finished product.

The large-format 3D printers in the XPRO line were created precisely to meet industrial needs.

3D printed functional parts can have different mechanical performance corresponding to the material chosen and the type of 3D printer.

DISCOVER STEREOLITHOGRAPHY 3D TECHNOLOGY (SLA)

Stereolithography is the most advanced additive technology on the market, as it achieves levels of precision not reached by other technologies.

Stereolithography is the most advanced additive technology on the market, as it achieves levels of precision not reached by other technologies.

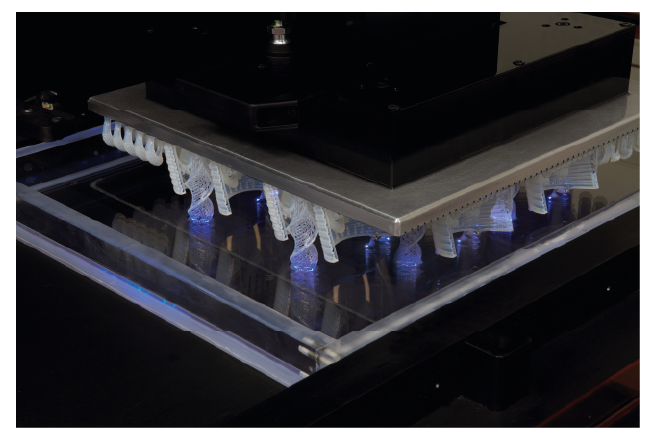

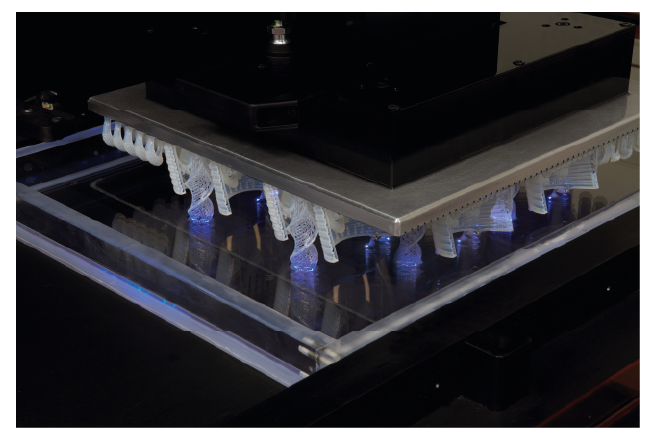

It consists in the polymerization of the liquid resin present in the tank through a luminous laser source.

In the case of DWS 3D printers, the laser source of class 3B, is developed in-house in the research and development centre.

The resins developed by DWS are photosensitive, therefore the emission of ultraviolet rays solidify the affected layer.

The printing area present in a SLA 3D printer is composed of three main parts:

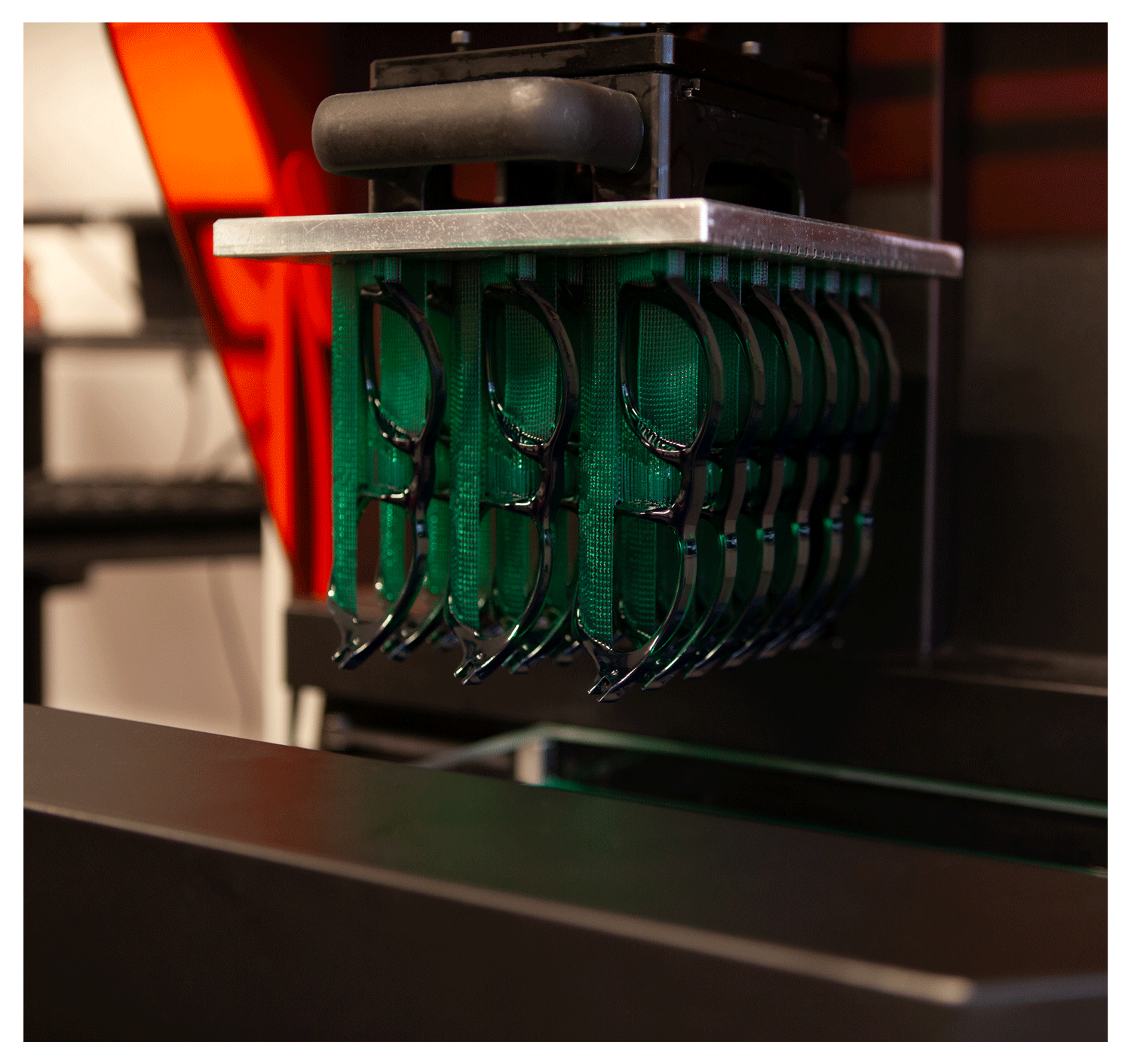

- The printing platform

- The resin containment tank

- The luminous laser source

The 3D modelling file is imported into DWS software:

- Nauta prepares the 3D model on the printing platform by designing the appropriate support

- Fictor sends the file, previously supported by Nauta, to the printing start-up phase and manages the execution of the work.

Having started the 3D printing process, the platform descends into the tank containing the resin and the laser solidifies the first layer from the centre to the outline of the object.

The operation is repeated until the part is completed.

Once the part has been removed from the platform, it is cleaned in a solvent solution to remove any remaining liquid material.

The curing process is then completed in a UV oven and with heat treatment if necessary, depending on the material chosen.

Stereolithography is the most advanced additive technology on the market, as it achieves levels of precision not reached by other technologies.

Stereolithography is the most advanced additive technology on the market, as it achieves levels of precision not reached by other technologies.