XCLUSTER CHAIN:

CHAIN MANUFACTURING GOES DIGITAL

XCLUSTER CHAIN is based on the XCluster® technology, that combines high-resolution 3D printing with lost wax casting in a fully digital workflow. Thanks to the combination of new castable materials, stereolithographic 3D printers and specially developed software, production becomes fully digital and automated.

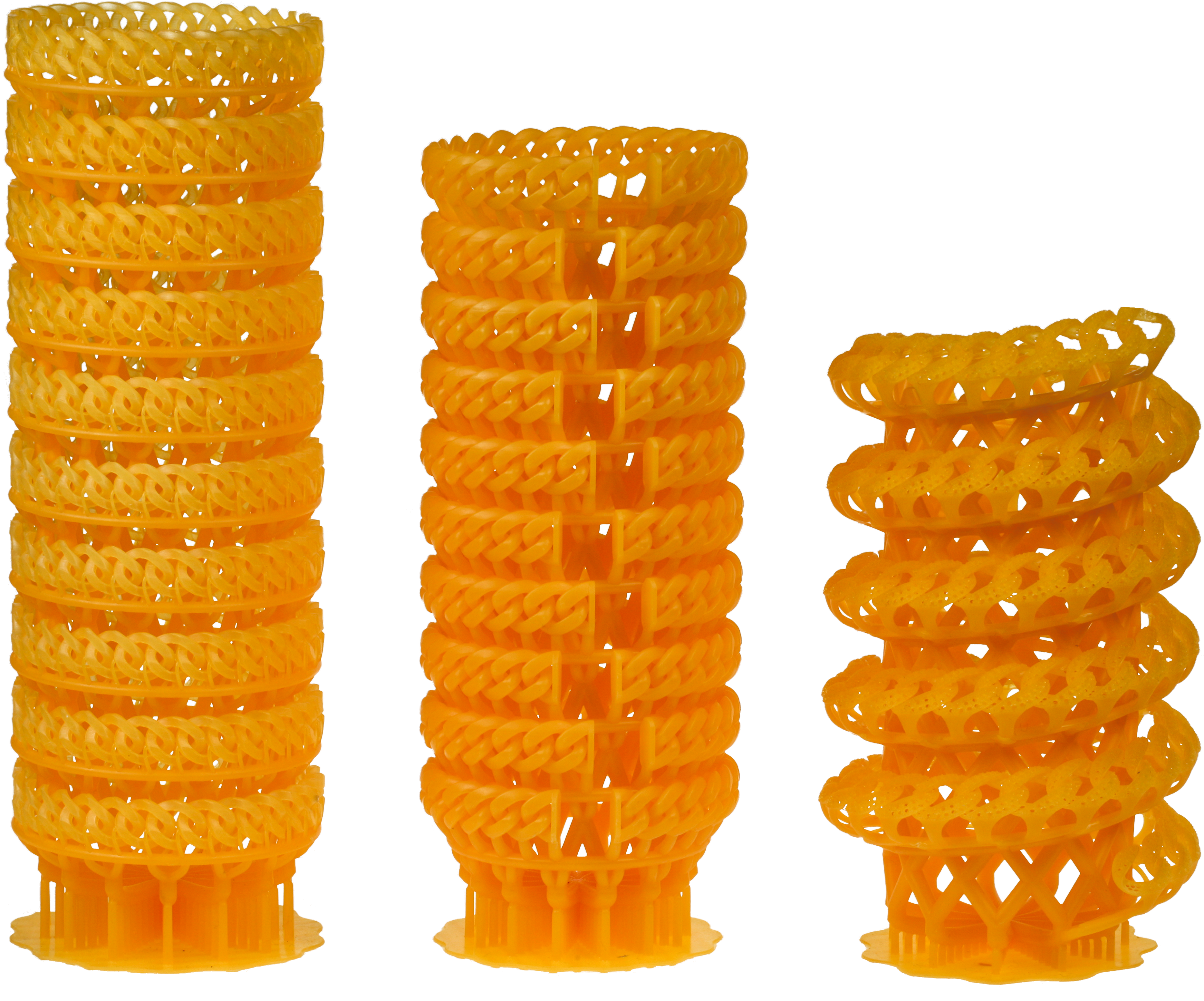

The concept of casting tree has been completely changed, replacing the central core with all the branches with a new geometry called cluster.

The absence of the central core allows to have an higher density and efficiency, therefore many more objects in the same flask and a much lower amount of metal. A single cylinder can include up to 2,000 objects of any complexity.

The traditional method and its limits

Even if conventional chain machines have been constantly improved over the past decades, their processes still meet big limits given by a purely mechanical application.

Besides this, it is uneconomical to print small quantities rather than few pieces.

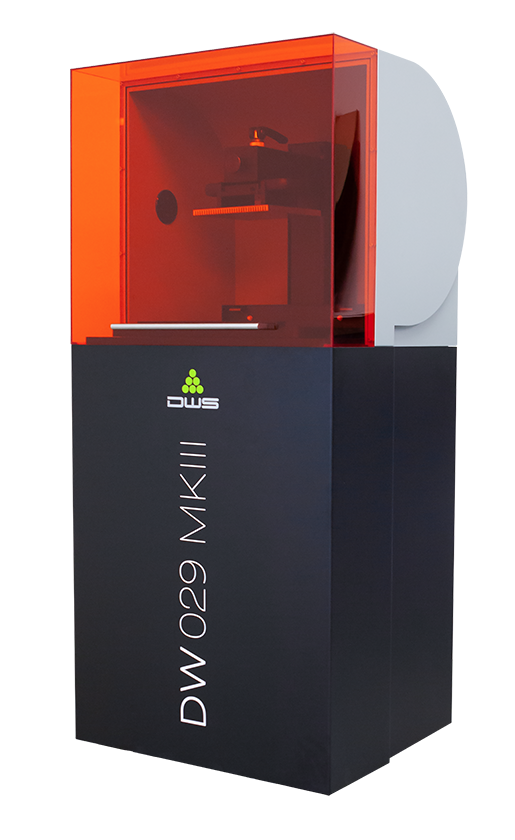

The DWS solution

The development of DWS’ XCluster Chain completes the workflow with a direct link between 3D printing and casting. Now it is possible to fulfill designs and qualities, even mechanical, that before it was difficult to work out.

XCluster Chain is not just a replacement technology, but it aims to exponentially increase creativity and then market outlets. So not only we can get already linked, welding-free chains that have never been done before, but also get qualitatively better products, without all the interventions typical of conventional production.

Nauta XCluster Chain software is able to automatically prepare the file and the production that you will set in the printer. It is however possible to modify any parameter anytime. Starting with sizing the diameter of the cluster to fit the flask, the software manages both the desidered length of bracelet/necklace and all the necessary casting sprues, by the use of a spiral construction. For the maximum flexibility, different type of designs can be generated inside the same cluster. Lastly, the software places the cylinder in the working area of the available printer, ready for the printing phase.

Features

- High resolution and precision

- No limits in geometrical complexity

- Best repeatability and scalability

- Increase of the productivity, reduction of the production time and costs

Details & strengths

XCluster Chain system makes it possible to:

-

Print high resolution and precision elements to go straight towards direct production

-

Possibility to produce customized and in even small quantities or unique pieces

-

Flexibility for a maximum freedom to use new geometries, extraordinary forms and complexities, so to produce completely new products: hollow chains, presetted stones, shapes, weights and tactile behaviors that cannot be obtained with conventional techniques

-

Scalability by adding more printers to manage all types of production lots

-

Elimination of the traditional metal processing phases, like welding, threading and hollowing. Through the software it is possible to get chain already linked, in some cases with the claps already assembled and all this without welding

-

Completely lean digital process that goes from the computer to the lost wax casting in two steps: the production workflow is drastically shortened

-

Real time production: allow to produce what is needed without storage

-

Thanks to a wide range of printers, this system is suitable for companies of any size, including small enterprises and independent professionals

-

User-friendly: easy and intuitive to use

-

The rationalization of metal management (precious and non-precious metals)

-

Absolute repeatability, thanks to a fully digital process

-

Specialized workers are not required and extensive training can be avoided. No need of specific skills to approach this job

-

Time saving: several conventional processes are eliminated

-

Fits perfectly the requirements of industry 4.0 due to the digital process

-

Faster and quicker to introduce new ideas, new collections

-

Cost reduction