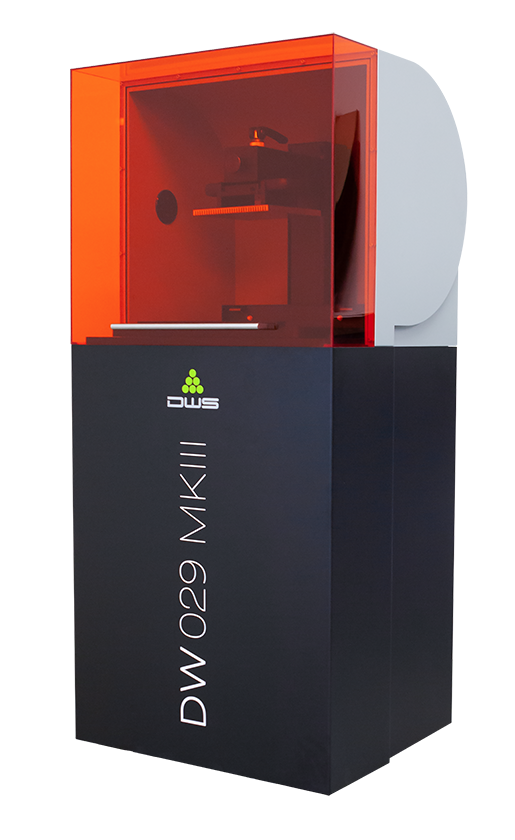

MANUFACTURING

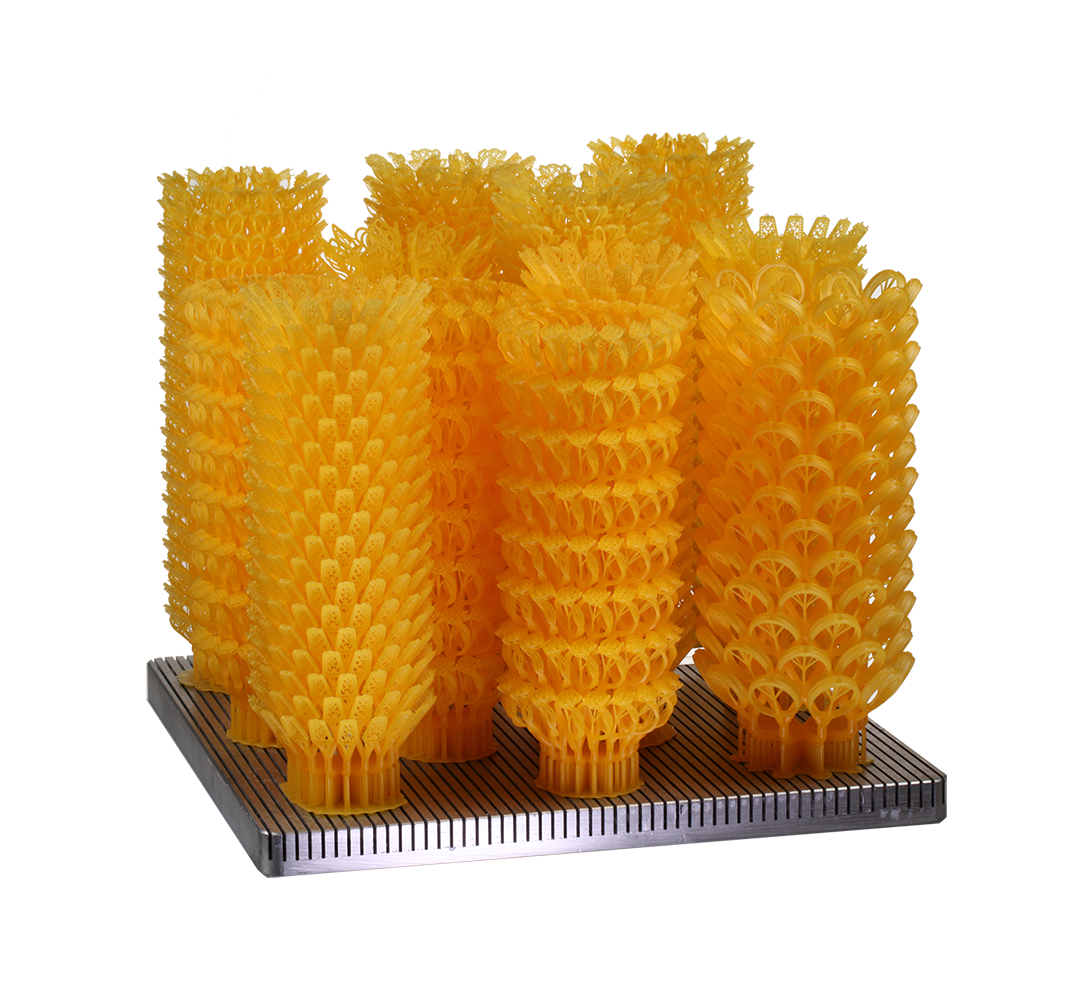

- DENTAL AND MEDICAL

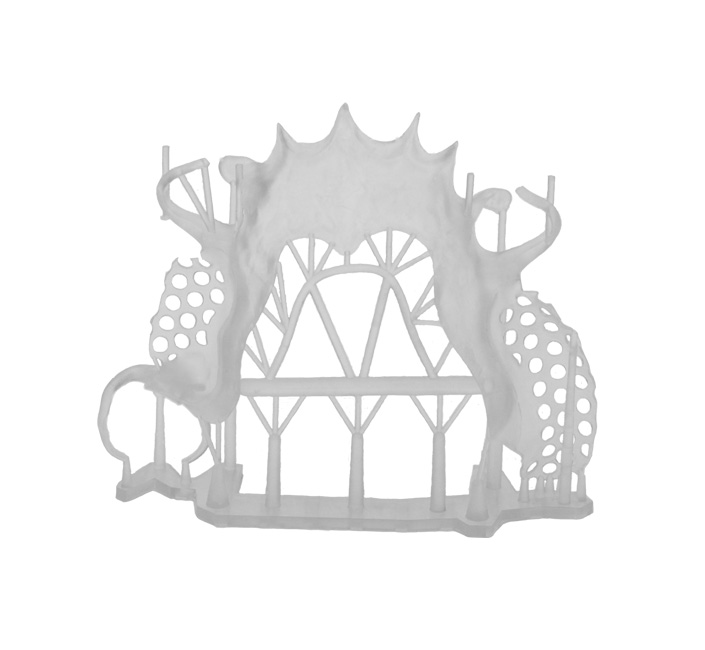

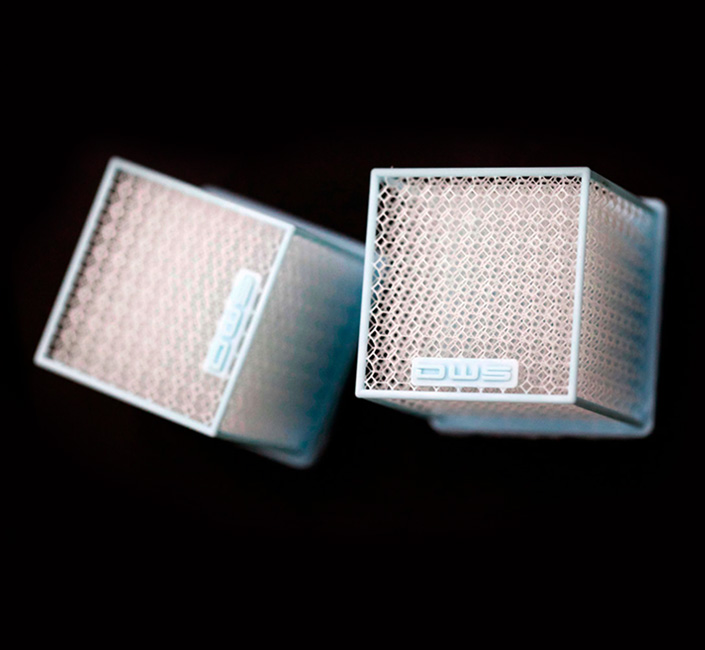

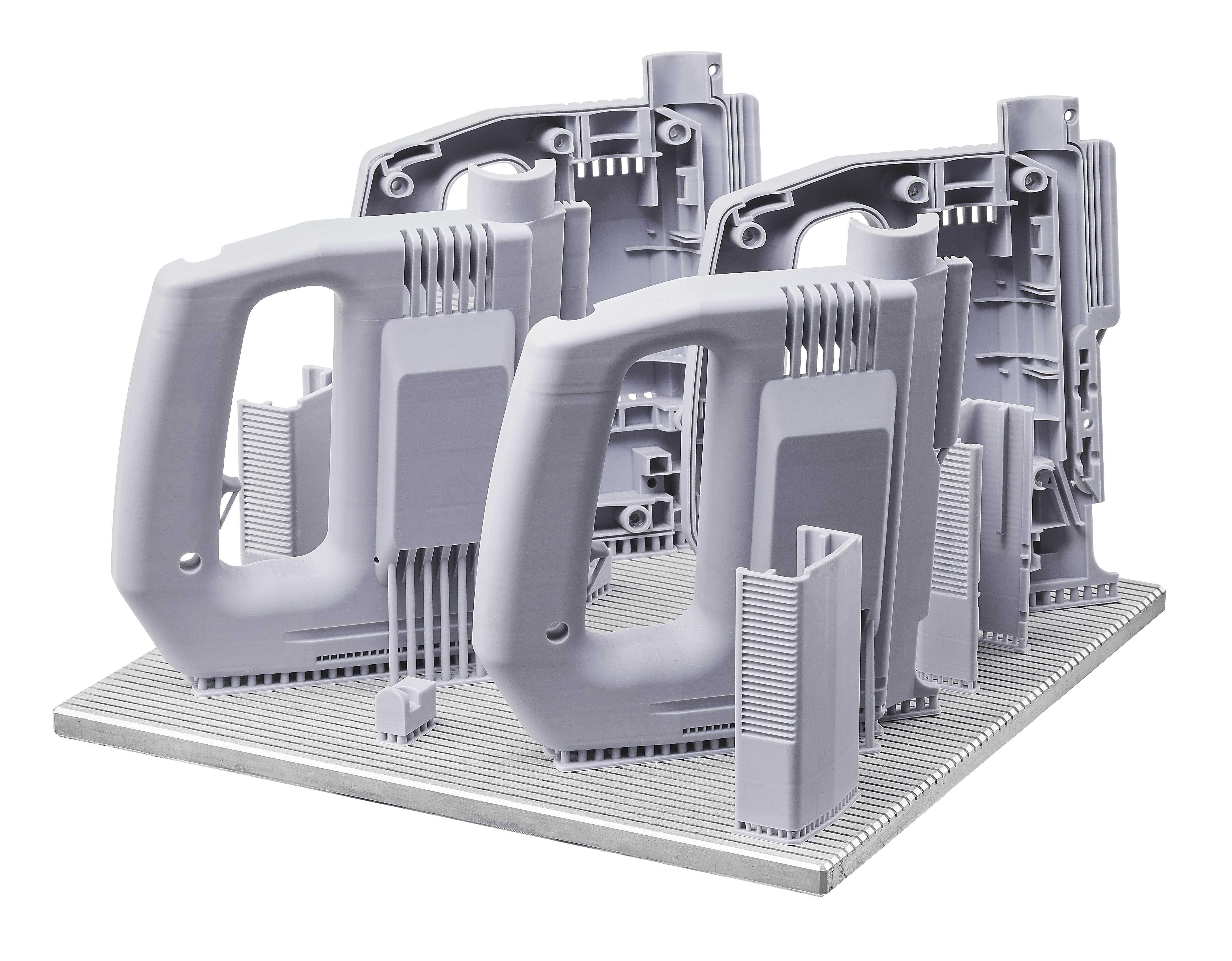

- MANUFACTURING & DESIGN

- Gear VR

- Sculpture - Chicken Killer

- Helmet

- Donation Robot

- Lamp - Cartabianca

- Turbine For A Photocatalytic Pigment Reactor

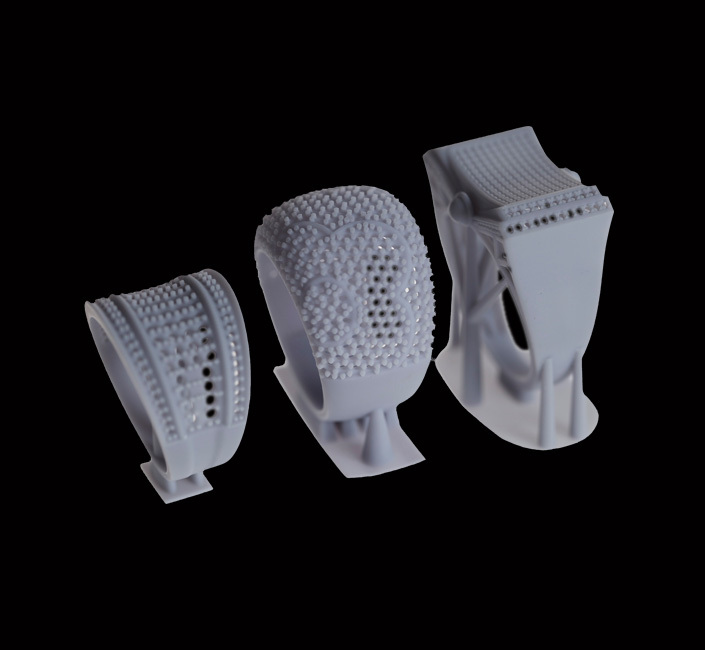

- Ski Boot Levers

- Drone Propeller Guard

- Le Yacht Lodge

- Reproduction of the town of Amatrice

- Half Toys

- Prototype electric car

- Skipper - Personal Refresher

- Sculpture - The Birth of Venus

- Automotive - Illuminated Steering Wheels

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)